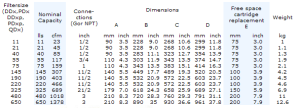

DDx, PDx, DDxp, QDx

If Compressed air is the energy source behind your production, you depend on its economic and efficient operation.

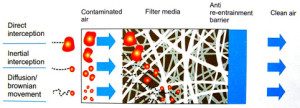

Every cubic meter of air contains 140 million particles of dirt. These particles, mixed with water vapour and hydrocarbon vapours from unburnt fuels and industrial processes, are drawn into the compressor and concentrated under compression. After compression. all these contaminants can combine in the piping system with condensed moisture, pipe scale and rust, creating a damaging abrasive emulsion. Atlas Copco has developed a perfectly matched filter system, which reduces all types of contamination right from the source according to your individual requirements.

Atlas copco offers you 5 ranges of filters:

- DDx range: Coalescing filters for general purpose protection, removing liquid water and oil aerosol to 0.1 mg/m (0.1ppm) and particles down to 1 micron.

- DDxp range: Particulate filters for dust protection, removing particles down to 1 micron. DDxp range: Particulate filters for dust protection, removing particles down to 1 micron.

- PDx range: High efficiency coalescing filters, removing liquid water & oil aerosol to 0.01 mg/m (0.1 ppm) and particles down to 0.01 micron.

- QDx range: Active carbon filter for removal of oil vapours and hydrocarbon odours with a maximum remaining oil content of 0.003 mg/m (0.003 ppm) should installed after a PD filter.

Energy costs of high pressure drop

Atlas Copco’s filters are designed to combine maximum contaminated removal efficiency with minimum pressure drop, resulting in a low energy consumption in your compressed air system keep in mind that 150 mbar extra pressure drop will cost you, 10,000 KWh extra energy per year in a 500 I/s compressed air system operating at 7 bar,6,000 hours per year.

Features

Specification

Benefits